21 September 2024

In marketing, distributors are reseller businesses appointed by producers and manufacturers to facilitate wider geographic distribution of their products or services. They sometimes add value by providing installation, training, service, and spares. Distributors typically work with multiple manufacturers acting as intermediaries to connect producers with their end-user markets.

Why do producers need distributors?

Manufacturers can and often do deal direct with end-users. This is termed direct distribution. Working through distributors (and other intermediaries) is called indirect distribution.

Distributors provide the manufacturer with the following advantages...

- Access to high-volume end-user markets: Many products need to be available alongside similar products to have a chance of being bought. This is particularly true of FMCG (Fast Moving Consumer Goods). Soap powder, fruit and vegetables, milk, butter, pickles, and headache tablets need intensive distribution to supermarkets and similar retail outlets. Similarly with plumbing products (copper pipe, PVC pipe, hot water heaters, taps and plumbing connections and fittings) are sold through hardware stores and specialist plumbing retailers. Hundreds of product categories are distributed using retail distribution.

- Reduced capital tied-up in finished goods inventory: As soon as a product is manufactured, the manufacturer would prefer to sell it as soon as possible to get their money back (raw materials, factory labor, and other ovrer heads). Filling a long pipeline of product into various geographies where it spends time waiting to be transported, loaded on ships and trucks, and sitting in warehouses - soaks-up a huge amount of capital. Selling bulk product to a distributor at the start of the supply chain solves this problem.

- Outsourced logistics and sales: Many manufacturers find it easier to use distributors to service a multiplicity of customers rather than set-up sales offices in a range of geographies (for example in each capital city and large regional cities, or even in overseas markets). Distributors already have the infrastructure, sales people, and customers that the manufacturer can leverage.

- More efficient transport and warehousing logistics: manufacturers would prefer to ship semi-trailer loads of product to one customer rather than deal in smaller quantities. The per unit rate of shipping in bulk is much lower than sending the same quantity of product in smaller shipments. The distributor takes these bulk shipments, puts them into their warehouse and fulfills smaller orders to customers in their local geographic area.

- Faster order fulfillment: The distributor warehouses product closer to end user markets speeding-up order fulfillment. Local warehousing acts as a buffer against the vagaries of transport logistics and manufacturing delays.

- Added value services: distributors have better local knowledge, undertake sales promotion, and often provide additional services to support the product.

Choosing to use distributors over investment in company owned sales offices and warehousing infrastructure in multiple locations, comes down to strategy and economics often driven by product size, sales volumes, and sales complexity.

As a general rule the lower the price and higher the sales volume - the more likely the product needs to be sold through distributors.

Terminologies used when talking about distributors

In marketing language....

- Indirect distribution strategy: using distributors to facilitate getting product to market is termed an indirect distribution strategy.

- A distributor is a sales channel: marketers use the term sales channel when talking about the path the product takes to get to market.

- Types of distributors: wholesale distributor, retail distributor, import distributor, technical product distributor, franchised distributor, dealer, and value-added reseller are all specific examples of "distributors."

- Sales agent: is not strictly a type of distributor. Properly speaking, a distributor buys and sells product. Sales agents don't, even though they facilitate sales and are included in the term "sales channel."

"Distributor" is not a precise term

"Distributor" has come to mean any kind of business that acts as an intermediary between a manufacturer and the end-user market.

In many industries the term distributor is used interchangeably with the term wholesaler. And this confusion is largely due to the way different industries structure their sales channels, and often it is just the customary use of terminologies peculiar to different industries or businesses

Traditionally, wholesalers and distributors had distinct roles in a two level supply chain:

- Distributors: Work closely with manufacturers to distribute products to various entities, including wholesalers, retailers, and sometimes directly to consumers. They often have contracts with manufacturers that include sales targets, and are involved in promotional efforts to boost sales. They don't just supply they also help develop the market. The relationship between the distributor and supplier is often informally referred to as a "partnership" as both work together to grow sales.

- Wholesalers: Work closely with retailers to keep them stocked. Manufactures and distributors supply wholesalers in large quantities ('wholesale quantities") who then sell smaller quantities to retailers. They focus on bulk buying and reselling, often without engaging in promotional activities beyond promoting their products to retailers. Wholesalers generally have no obligation to purchase products from any particular distributor or manufacturer other than price incentive in the form of favorable spot deals on individual purchases, or volume rebates. They are treated as customers of the distributor or manufacturer.

In the traditional strict use of the terms, wholesalers primarily deal with bulk sales to retailers, while distributors manage the broader distribution network and often have a more direct relationship with manufacturers. But in Australia, a flatter single level distribution channel is preferred...

The broadening definition of the term "distributor"

The lines between the wholesaler and distributor definition are burred:

- The volume of product sold and the average price: Low value high volume products like FMCG require intensive retail distribution requiring more complex sales channels. This is where traditionally you would find a Producer -> Distributor ->Wholesaler -> Retailer - > Consumer sales channel. But...

- Disintermediation: The increasing trend toward shortening sales channels to remove middle-men from the chain to reduce cost. Large chains like Bunnings, Coles, Woolworths and others increasingly seek to deal direct with the import distributor or Australian based manufacturer by-passing traditional distributor and wholesaler intermediaries.

- USA versus Australian population sizes: Many of these sales channel models and terminologies originated in the USA and Europe where sales volumes are larger, and geographies are more complex than they are in Australia.

- Growing use of 3PL in place of distributors aided by the internet: Import distributors and manufactures are increasingly solving the problem of stocking their product closer to customers in different states by using 3PLs (third party logistics). These are outsourced warehousing and product dispatch businesses. The import distributor or manufacturer stores their finished goods at the 3PL (the 3PL doesn't buy the stock as a distributor would) and dispatches it to the customers when it is sold. Sales are handled direct to customers facilitated by the internet.

- B2C or B2B: When the end-user (final purchaser of the product who actually uses it) is a business, the terminologies tend to be more business oriented. The point being businesses like to think they are buying from the wholesaler or distributor rather than "a shop". However, the term "wholesale distributor" is more likely to be used in the B2B context and "retail distributor" more for B2C. Some retailers market themselves as "wholesalers" or "warehouses" to give the impression of lower prices.

Irrespective of commonly agreed terminology, what is meant by distributor in the broad sense is fairly clear. What specific function they serve is customized and these functions are specified by the distributor agreement - a legal document based on what has been agreed between the manufacturer and the distributor.

Characteristics that all distributors have in common

While the term distributor has many variants, all distributors....

- Independent: Are businesses that operate independently from their suppliers.

- Represent multiple manufacturers: a distributor typically trades products produced by multiple suppliers.

- Distributor agreements: Have a formal business agreement with their suppliers. In contrast, a business described as a wholesaler generally doesn't have supply agreements but purchases on an as needed basis often shopping for the best price at the time. For example a wholesaler of fruit and vegetables, or timber.

- Are traders: Buy and sell product hence they are often referred to as "resellers". However, I favor the term "distributor" because their main purpose is to achieve greater geographic distribution.

- Distribute products: Provide reach into geographic locations that their suppliers would find hard, inconvenient, or costly to replicate.

- Specialization: Distributors mainly focus on similar products for example automation components, fluid power components, paints, door furniture, industrial drive components. Specialization makes it easier for potential customers to seek them out and for the distributor to develop technical knowledge and industry expertise. Specialization also improves the ability for them to efficiently fulfill customer orders with mixed supplies. For example someone buying an industrial gearbox might also order a service brake, drive couplings, pulleys, shafts, an electric motor, and a VSD drive. Each of these components would be from the different manufactures they represent. Further, specialization attracts enquiry from other manufacturers seeking distribution for their similar products, thus growing the distributor's product portfolio.

- Are middle men: Act as intermediaries between the producer/manufacturer and their end-user markets.

- Have their own customers: The main advantage to the supplier in appointing a distributor is that the distributor already has customers they can immediately supply the product to.

- Actively promote: Distributors do more than just warehouse the product closer to the end-user markets. They also actively promote it. Distributors often have sales teams, actively promote online to drive traffic to their websites, participate in trade-shows, and run product demonstration events. Most distributors actively work to promote their own brand and capability as a supplier of products in their area of specialization.

- Logistics: Distributors maintain an inventory of products close to end-users and arrange packing and shipping. Being able to supply product quickly (compared with waiting for it to be shipped from the manufacturer) is their main competitive advantage.

Distributors make money on the difference between the buy price and sell price of the products.

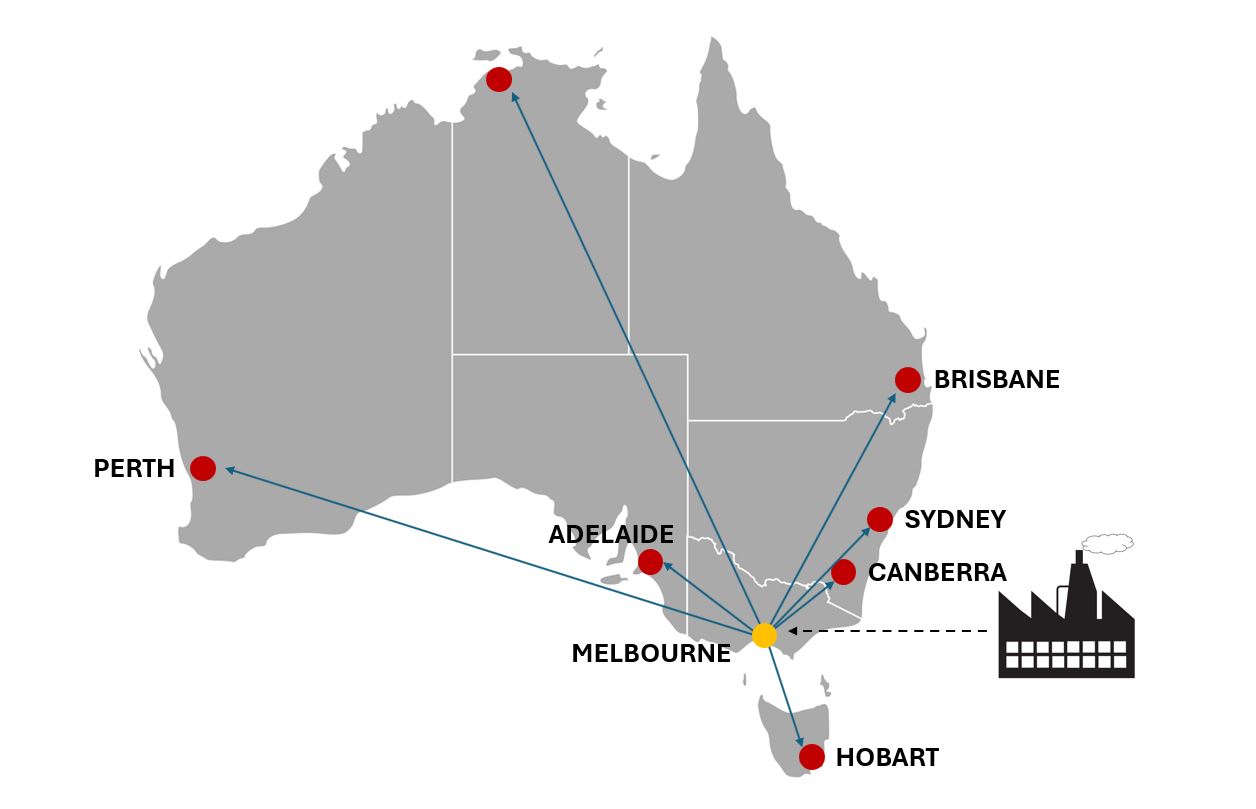

An example: distribution for a manufacturer

Consider a hypothetical manufacturer of industrial machinery located in Melbourne. The typical ex-factory price of their products is AUD$5,000.

In the above diagram we see the manufacturer sells DIRECT to its local customers (within the state of Victoria) but appoints distributors to sell products from capital cities in each of the other states. This is faster, cheaper, and likely more effective than setting-up its own sales teams and warehousing in each of those locations.

Each of the red dots is the location of the distributors.

The advantage for the manufacturer is....

- Expansion of geographic reach: It now has representation and product in all states not just one.

- Expanded customer base: Each of the distributors already have customers in each state. And/or are better placed to find new customers.

- Faster delivery: customers from other states could buy direct from the Melbourne based manufacturer but there would be considerable road freight delays. In the case of Perth and Darwin shipping would be as long as 5 days from Melbourne (Perth is 3,460 kms from Melbourne by Road).

- Installation and commissioning: some equipment requires expert install and set-up. Distributors can provide this service.

- Local service: For equipment that requires after sales service, repair, handling warranty claims, selling spare parts, consumables, and accessories - the distributor often also provides this function.

- Training: If required, the distributor can provide user training.

All of the above functions facilitate increasing sales volume which for the manufacturer increases profits but also margins. Often manufacturers can readily handle increased production volumes through much the same investment in plant and equipment. Thus the overhead cost is amortized over more sale units.

In this context the manufacturer is using distributors that could be best termed "retail distributors", "dealers", or "value added resellers."

Value-added reseller is a term that describes a distributor that does more than just sell the product, they also provide services that support the sale such as installation, training, after-market servicing etc.

Business relationship and the cost of distributors

Distributors purchase the product from the manufacturer and take delivery of the product and place it in their warehouse and/or on their retail shelves.

The distributor is effectively the manufacturer's customer. However, the relationship between the manufacturer and the distributor is usually symbiotic; both working together to develop the market and drive sales. The manufacturer will undertake promotional activity to build brand awareness and re-direct sales enquiries to the nearest distributor.

And distributors contribute by actively promoting the product in their geographic region and have their sales teams introduce the product to their customers.

Distributors profit from the relationship by adding a margin to the product cost.

Typically for manufactured products, distributors make 30 to 50% GP. Thus, if the manufacturer sells a product for $5,000 to the distributor, the distributor will markup the price by 43%. The sell price becomes $7,143.41 yielding the distributor a 30% GP or $2,143.41 gross profit.

The next question becomes "wouldn't the manufacturer be better off selling the product direct to the customer and pocketing the additional $2,143.41 ?"

Of course they would, but they would need to get the sale in the first place. The purpose of appointing distributors is to improve reach into other geographic regions.

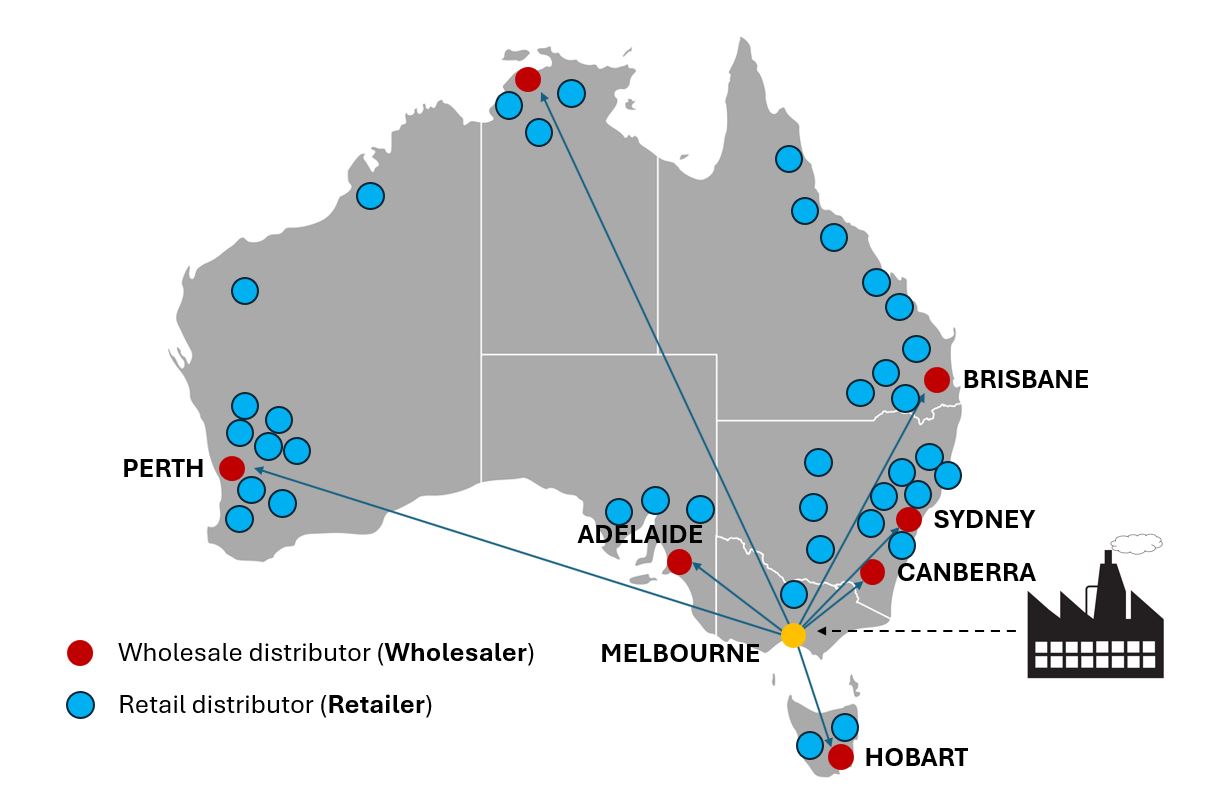

Wholesale distributors versus Retail Distributors

While some people use these terms differently, generally speaking....

- Retail distributors: Sell the product to the final end-user. In the above example of the Melbourne based manufacturer, the distributors in each capital city would be called retail distributors. Having a traditional shop front isn't the defining feature. Many distributors in B2B markets operate from warehouses that their customers rarely visit.

- Wholesale distributors: Sell the product to other retailers. Thus, the purpose of the wholesale distributor is to develop and service a network of retail distributors to encourage them to stock the product and to support their efforts to sell it. Their value is that they have an existing relationship with many retailers and have the representation able to promote your product and convincing them that offering it for sale would be good business for them. They also provide stock nearer to them so they don't have to wait for it to come from the factory.

The following illustrates the wholesale distribution concept...

Now there are "two mouths to feed" on the path from the manufacturer to the end-user. The wholesaler adds their margin to the cost, and then the retailer adds another margin.

A typical retail margin would be a 50% mark-up yielding 33% GP (but varies considerably by product and industry. A dress boutique for example might mark-up by 200%).

Thus, the Melbourne based manufacturer's product is sold by the wholesaler at $7,143.41 to the retailer, who then adds another 50% increasing the final sell price to the retail customer (end-user) to $10,715.12.

The product left the factory at $5,000 and ends-up costing the final customer $10.715.12 - more than twice the price.

Actually, it's worse than that because we haven't included the cost of freight and GST. However, a two level distribution channel for industrial machinery is unlikely in Australia because the price becomes un-competitive as can be seen. But, the example illustrates the cost of distribution.

As a rough rule of thumb: Typically the final retail price of products is 2 to 3 times the ex-factory price. Distribution costs money.

Selling direct competing with distributors

In the above example, the Melbourne based manufacturer sells direct to its Victorian customers, but sells via distributors interstate. In a single level distribution channel (retail distribution with no wholesaler in the chain) the manufacturer has a 30% price advantage versus the distributor. Some interstate customers might discover this and place their order direct with the manufacturer thus cutting out the distributor. This is not a sustainable business model as the distributors quite rightly will get upset potentially ending the relationship.

Best practice would be for the manufacturer to sell direct but at the recommended retail price, aiming to be not dissimilar in price to the distributor. The customer would have little advantage buying direct and would also miss out on the faster delivery and other benefits the local distributor could provide. And this would be normal.

However, two problems can arise, discussed below...

Split channel distribution

What if a large mining company located in (say) Western Australia bypasses the distributor and contacts the manufacturer in Melbourne and says "we want to place an order for 150 units, can you provide us with a special price?"

150 units @ $7,143.41 is a million dollar order and the opportunity can't be ignored.

The manufacturer knows they can go down to $5,000 per unit (or even lower) to win the business. But, in so doing they will cut the distributor out and damage the relationship.

Some mining company procurement people have a policy of trying to bypass the distributor (even if not placing a large order) because they know the distributor is adding a margin.

Here are the usual ways of addressing this situation:

- Discuss it with the distributor: There is a high probability they will find out if you make the deal. Particularly if they introduced the product to the customer in the first place.

- Refer the customer back to the distributor: Inform the customer that they must work through the distributor but you will help the distributor by providing lower ex factory pricing on this deal. The distributor then has the opportunity to decide how low they need to drop their own margin to win the business.

- Pay the distributor a commission: If the business cannot be won at normal margins (often the case) then you will both lose the order. Better to write the business but share with the distributor the profits.

- Set-up a split channel distribution agreement from the start: Many organizations either manufacturing in Australia or importing product from overseas have a policy of dealing direct with large accounts and servicing small accounts through distributors. The cut-off point between small and large is typically annual sales of AUD$1.0 million. This way the rules are clear from the start. This doesn't eliminate stepping on the distributors toes but reduces the conflicts to a more manageable level.

Now this is a simplistic example because other factors might come in to play that make the deal easier to live with. 150 pieces of machinery might well need installation, servicing, and future spare parts etc.

The distributor is geographically located closer to the mining company and would be the logical choice to perform this work. This ongoing revenue stream can often be more lucrative than the original supply contract.

Larger supply contracts take time to consider as the buyer is seeking to test the market to obtain maximum value (not always lowest price but that is a primary consideration). The need to supply quickly is taken out of the equation, negating one of the distributor's main competitive advantages and exposing their price disadvantage.

Price control and channel conflict

Channel conflict is a term used to describe situations where businesses in the distribution channel compete against each other. For example the Sydney and Brisbane based distributors are dealing with the same customer.

Two important points about the Melbourne based manufacturer example mentioned above...

- Distributor independence: In this example, each distributor in each state are separate businesses. While they both distribute the same product manufactured by the Melbourne company they have no allegiance to each other and act in their own interests.

- Price independence: Distributors set their own retail price. The manufacturer can recommend or suggest a price but in Australia it is illegal to coerce the distributor into selling at a specified price. They can sell it at whatever price they want. It is also illegal for the distributors to agree on a price between themselves. This is called collusion or price fixing.

According to the ACCC website...

- Suppliers can recommend prices, for example, by providing a recommended resale price (RRP) list.

- Suppliers can set a maximum retail price.

- Suppliers can refuse to supply resellers that engage in loss leader selling.

Refer ACCC website. Professional legal opinion is recommended.

This sets up a potential situation for one distributor to infringe on another distributor's territory either knowingly or not. One distributor could be selling the same product made by the manufacturer for a lower price thus attracting customers from outside their agreed territory.

This problem has been exacerbated by the rise of the internet making price discovery more efficient for consumers but worse many distributors set-up online shops to complement their physical presence. This almost guarantees that distributors will sell to customers from outside their assigned territory.

So while these problems (and others) arise regularly, they are not insurmountable and are usually resolved through correctly structured distributor agreements (specialist solicitors are well versed in advising on and drafting distributor agreements), and through discussion and negotiation. This raises the issue of the other costs of operating a distributor network - the time and direct cost of setting-up and managing distributors.

Channel management

Channel management in product distribution refers to the strategies and processes a company uses to manage and optimize the various pathways (Channels is the popular term in marketing parlance) through which its products reach the end customers. These pathways, or channels, can include distributors, wholesalers, retailers, and even direct sales.

Effective channel management involves:

- Selecting the right partners: Choosing distributors, retailers, or other intermediaries who can not just effectively reach the target market, but have a corporate culture that aligns with your own.

- Coordinating activities: Ensuring all partners are aligned with the company's goals and strategies. This can only happen if they have been briefed and to some extent have had some input. A common activity in channel management is the development of joint business plans. This is a more explicit statement defining specific aims and objectives and assignment of responsibilities for the forthcoming business period. It answers the question "what specifically will we each be doing in the spirit of working together to develop sales for our mutual benefit?"

- Monitoring performance: Tracking the effectiveness of each channel and making adjustments as needed.

- Building relationships: Like any relationship in business or life, relationships need to be nurtured. Trust, respect, and esprit de corps is built over time but also requires skill. Working with distributors is rarely set and forget.

- Training and development: Distributors will find it more difficult to sell your products if they don't understand them and haven't been taught the best method of promoting and selling them.

- Channel marketing: Having a person or people in your marketing team tasked with supplying distributors with marketing materials (brochures and other sales aids, display materials, advertising assets, photographs, video, safety data sheets etc.) and doing so expeditiously will make it easier for them to spend money promoting your products. When you look on their website and see shitty and out of date images of your product - that's most likely your fault; when they requested images some junior in your team took the easiest path and sent them the first picture they could find.

Distributors are independent businesses that sell multiple products on behalf of multiple businesses (if they only sell your product they might more properly be called a dealer or a franchise). This means they will prioritize their resources toward selling the easiest products in their portfolio.

The aim of channel management is to make the distributor's priority selling your products. Because you make doing so easier and more profitable.

Further reading

Place strategy and distribution

Direct distribution

Indirect distribution

What is an import distributor?

Technical product distributor

Franchise distributor

What is a sales agent?

What is channel marketing