09 May 2023

Understanding indirect distribution: expanding market reach through distributors

When developing marketing strategy, companies need to choose between selling direct to end-users (customers also known as consumers) or to sell their products via distribution channels, where their immediate customer becomes another business who buys the product and then adds a margin and on-sells to end-users. This latter approach is termed "Indirect distribution". Some organizations use a mixture of both.

Retail distributors (shops) are the most obvious form of indirect distribution. Supermarkets for example BUY product from manufacturers/producers, stock it on shelves, and customers browse those shelves, select their items, and pay for them at the checkout.

Clearly the availability of the products close to where the customers live is a major convenience and therefore a powerful sales multiplier for the manufacturer/producer.

This is the primary purpose of indirect distribution.

But it isn't applicable to all products and services.

A "Distributor" can take many forms. Read what is a distributor? for a detailed explanation.

Introduction

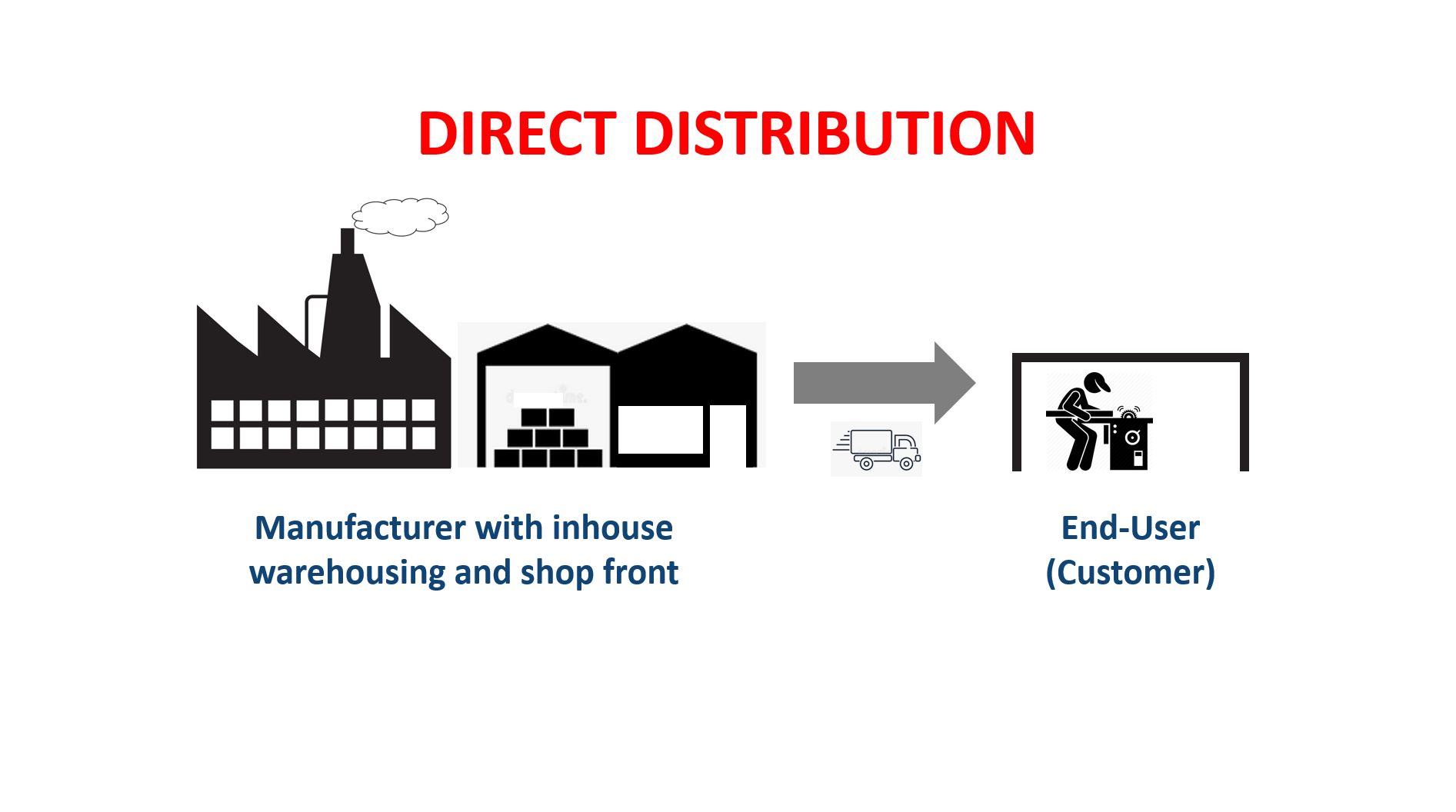

Manufacturers either SELL DIRECT to their end-users or sell first to INTERMEDIARIES (Distributors), who then on-sell the product to end-users.

Direct Distribution: the manufacturer sells direct to their customers.

Indirect Distribution the manufacturer sells to wholesale distributors (one or more), who take the product into stock. The wholesalers then sell to retailers. The end-user buys the product from the retailer.

The Wholesale Distributor ("wholesaler") and Retail Distributor ("retailer") are also known as "intermediaries" and together they are referred to as a "sales channel".

The sales channel can be a two step process as shown in the above diagram, or a single step where the manufacturer sells direct to retail distributors.

Selling via intermediaries is called INDIRECT distribution.

By leveraging indirect distribution channels, companies can expand their market reach, optimize resource allocation, and create mutually beneficial relationships with intermediaries. In this article, we will explore the concept of indirect distribution, its key components, benefits, and best practices for successful implementation.

Defining Indirect Distribution

Indirect distribution, also known as channel distribution or distribution through intermediaries, refers to a marketing strategy in which goods or services are delivered to consumers through an intermediary network.

Unlike direct distribution, where companies sell their products or services directly to customers, indirect distribution involves partnering with intermediaries such as wholesalers, retailers, agents, and resellers to facilitate the movement of goods or services to the end-users.

Key Components of Indirect Distribution

-

Intermediaries: Intermediaries (also called Distributors) are central to indirect distribution. The whole point of indirect distribution is that intermediaries sell to the market on the manufacturers behalf, overcoming the need for the manufacturer to deal direct with the end-users. They act as a bridge between the manufacturer and the end consumer. Intermediaries can be wholesalers, retailers, distributors, agents, or brokers, depending on the nature of the product and target market.

-

Channel Structure: The channel structure represents the arrangement of intermediaries involved in the distribution process. It can vary from a simple structure, involving a single intermediary between the manufacturer and the end consumer, to a complex structure involving multiple levels of intermediaries. Although it has to be said that in Australia multi-level channels are not common due to the small population (compared with say the United States). In Australia, import distributors may appoint individual distributors (or sales agents) in each state. Manufacturers based in Australia are likely to appoint distributors in each state. However, there are other combinations.

-

Logistics and Supply Chain Management: Indirect distribution necessitates efficient logistics and supply chain management to ensure timely delivery of products or services to the end consumer. This involves coordinating inventory, transportation, warehousing, and order fulfillment processes to minimize lead times and maintain adequate stock levels.

Complexities arising from indirect distribution

While the process of taking orders from distributors and shipping products to them sounds simple, there are many complexities that need to be managed by the product originator (manufacturer or import distributor). This leads to the need to employ staff to perform specialized functions, invest infrastructure, and build systems to support sales channels...

- The manufacturer may not have sufficient quantity in stock of all items. Necessitating shipping a partly fulfilled order and keeping track of the need to make-up the difference later.

- Errors can occur. Wrong products shipped. Deliveries to wrong address or the truck breaks down. Products damaged in transit.

- Each distributor may have different agreed pricing and this may be based on volume price breaks (discounts for placing bigger orders). These arrangements have to be tracked.

- In some distribution agreements rebates are paid after distributors have achieved sales targets, Again requiring tracking and often resolution when the distributors numbers don't agree with the product originator.

- Damaged goods need to be returned and claims assessed. Returned product needs to be either repaired, scrapped, or returned. Refunds have to be processed.

- Warehousing and dispatch processes can become complex when multiple distributors are being supplied to and each placing multiple different orders.

- To manage distribution at sufficient scale requires IT systems to track orders, warehouse picking and packing, freight brokering, shipping, proof of delivery, invoice dispatch and myriad other events and transactions. There is plenty of software, systems, and integrations available. But selecting them, configuring them, and keeping them running sweet is another cost and it ain't cheap.

- Many industries (and individual distributors) have varying and sometimes complex supply chains. For example some retail distributors (for example Bunnings in Australia) require their suppliers to freight direct to each store in their network (Bunnings for example has several hundred stores) and in most cases the supplier must place the product on to the shelf. Other retailers maintain distribution centres and freight product to each outlet themselves. Large retailers require suppliers to route orders and invoicing through electronic data interchange (EDI) with very specific IT integration that can take months to set-up (a rigorous testing and verification process required before the parties trust the integration and allow it to go live).

- Large retail chains (retail distributors) often have complex supply agreements involving competitive bidding, negotiated pricing, rebates paid to the supplier when sales targets are met, charging suppliers advertising subsidies, penalties for late deliveries, invoicing for damaged stock and a range of other "adjustments to invoices." Keeping track of all of these transactions and "if, buts, and maybes" becomes a major administrative task.

These are just some of the problems all of which are routine and daily in the life of managing distribution channels and require expensive IT systems (that themselves need to be supported) and warehousing staff are required to manage these processes and physically pick, pack, dispatch orders, and receive returned products.

Behind all of this is the need to constantly communicate with distributors to develop joint marketing plans and sales promotions, discuss issues, coordinate problem resolution, build and nurture business relationships.

Indirect distribution methods

There are a number of indirect distribution methods (or models), here is a list of the most common with links to detailed descriptions of each...

- Distributor

- Intensive distribution

- Selective distribution

- Exclusive distribution

- Franchising

- System integrators

- Technical product distributors

- Sales agents

Benefits of Indirect Distribution

-

Extended market reach: Indirect distribution enables companies to tap into new markets and reach a larger audience by leveraging the established networks of intermediaries. Through partnerships with wholesalers, retailers, and other intermediaries, businesses can gain access to customers they may not have been able to reach directly.

-

Cost efficiency: For companies with limited resources, indirect distribution offers cost advantages over establishing and managing their own distribution channels. By leveraging existing intermediaries, businesses can reduce expenses associated with infrastructure, warehousing, transportation, and staffing.

-

Speed to market: Leveraging distributors who already have established infrastructure, sales teams, and mature customer relationships can increase speed to market by tapping these arrangements can be much faster than building-out your own distribution network.

-

Reduced inventory: Once product leaves the factory and is shipped to the distributor, they are invoiced and storing the product becomes their problem. Whereas with DIRECT DISTRIBUTION (no distributors) the product originator would need much larger warehousing to store finished goods inventory. However, this is dependent on the type of indirect distribution arrangement being adopted. For example retail and wholesale distributors purchase stock whereas sales agents do not.

-

Expertise and support: Intermediaries possess valuable market knowledge, expertise, and customer insights. By partnering with experienced intermediaries, companies can benefit from their domain expertise, market intelligence, and customer relationship management skills.

-

Outsourced customer support and after-market service: Many products (for example industrial equipment,motor vehicles, air-conditioning, electronic equipment etc.) require customer support and servicing. Many distributors are already equipped to provide these functions including having established crews of service technicians, service vehicles, and workshops. The customer's decision to purchase your product may well be influenced by how easily they can obtain after sales support, repairs, and maintenance. The availability of local service can be a critical purchasing criteria. Some distributors actually make more money from providing after sales service and the sale of spare parts than from the sale of the equipment in the first instance. This is particularly true of motor vehicle dealerships.

-

Focus on core competencies: Indirect distribution allows businesses to focus on their core competencies such as product development, marketing, and innovation, while leaving the distribution logistics and channel management responsibilities to the intermediaries. This enhances overall efficiency and effectiveness.

Disadvantages of indirect distribution

-

Sharing of profits: Clearly the intermediary needs to be paid for their work and this cost is added to the price of the goods being sold. To maintain a competitive price for the end-user, this cost is usually taken from the manufacturer's profit margin. However, without the distributor the manufacturer would normally expect to incur considerable additional marketing and distribution costs if they sold direct to the market. Indirect distribution works best if the cost benefit of the distributor outweighs the cost benefit of selling direct.

-

Lack of focus: Many distributors also distribute products on behalf of many manufacturers. In some cases, they may even sell competing brands. The distributor may not put sufficient effort into promoting your products to maximize market opportunity. This may be for a number of reasons ranging from incompetency, finding it easier to sell other products, lack of staff, or making higher margins on competing products they sell. For distributors selling competing products (which is quite common) they don't really care which brand they sell as long as they get the sale. This can be overcome if it is possible to negotiate exclusive distribution.

-

The need to manage, nurture, and support distributor relationships: while distributors have existing customer relationships and access to markets that the manufacturer may not have access to, simply appointing distributors is often not enough. Since distributors have many products to sell, they have limited resources to allocate to individual products. To encourage them to take greater interest in promoting your product takes effort, consequently the manufacturer needs to allocate time (or employ specialists) to work on monitoring distributor performance, and providing support services such as training, working together on securing large accounts, and providing promotional support. Often manufactures also need to create demand (called "pull through marketing") by paying to advertise products that ultimately drive sales to distributors.

-

The distributor owns the customer relationship: Indirect distribution puts a barrier between the end-user and the manufacturer. Should the relationship with the distributor end, the manufacturer effectively depletes their customer base.

-

Market dominance and "the upper hand": Depending on the industry and product category some distributors have such a strong market reach and presence they can dictate terms to their suppliers. This is particularly true of supermarket chains and category giants in automotive after-market products, white goods, and consumer electronics. Such distributors dictate terms to suppliers on a "take it or leave it" basis. Conversely, in B2B markets for example global technology companies, the supplier has the upper-hand and being appointed a distributor is done on a "perform or we will find another distributor who can" basis. It needs to be said however, the most enduring relationships between suppliers and their distributors are those where the power balance is roughly equal and a symbiotic relationship develops.

Best Practices for Indirect Distribution

-

Partner Selection: Careful selection of the right intermediaries is crucial for successful indirect distribution. Consider factors such as reputation, market coverage, distribution capabilities, financial stability, and alignment of values and objectives.

-

Collaborative Relationships: Nurture strong, collaborative relationships with intermediaries based on trust, open communication, and mutual respect. Establishing a win-win partnership is essential for long-term success.

-

Clear Channel Strategy: Develop a clear channel strategy that outlines the roles and responsibilities of each intermediary, establishes pricing policies, defines territorial rights, and ensures consistent brand messaging across all channels.

-

Effective Communication and Training: Regularly communicate with intermediaries to provide updates, share marketing materials, and offer training programs to enhance their product knowledge and sales skills. This facilitates better customer engagement and promotes brand loyalty.

-

Promotional Support: Distributors often stock many brands and often competing brands. They aim to sell ANY product not necessarily YOUR product. However, the suppliers they find easiest to work with and help them to develop opportunities will receive higher priority and greater attention. Responding quickly to requests for promotional material (brochures, product photography, digital assets for their social media posts, display material etc.) and also providing advertising to create demand makes it easier for them take interest in and sell your product.

-

Slippery supply chain: fast processing of sales orders, holding stock, and fast processing of returned stock also helps make it easier for the distributor to do business with you.

-

Distribution Agreement: The expectations of both parties (manufacturer and distributor) should be incorporated into a distributor agreement. While a distributor agreement is a legal document, best results are achieved when it is thought of as a plan rather than a legal instrument. The distributor agreement would set clear guidelines as to the division of duties (this is what we will do, this is what you will do) toward achieving a successful partnership.

-

Performance Evaluation: Continuously monitor and evaluate the performance of intermediaries to ensure they meet the agreed-upon standards. Distributors who slip behind agreed sales targets should result in a friendly conversation in the first instance such as "is there a problem? What can we do to help?" Often simply indicating that you are watching and are interested is enough for them to put more effort into promoting your product. Distributors often have many brands and products to sell. The squeaky door gets the most oil.