27 June 2024

Import distribution: arranging the purchase and shipping of products from overseas sources and bringing them into country for local sales and distribution

An "Import Distributor" is a business entity primarily involved in the marketing and distribution of goods obtained from outside of their own country. The import distributor performs the function of bringing the product into the country and distributing within that country through various distribution channels. More than just performing the logistical functions of importing, the import distributor also undertakes market development promoting the product to build brand awareness and demand for the products that it imports. Many import distributors see sales and marketing as being their core business.

An import distributor is an IMPORTER + a DISTRIBUTOR and performs the functions of both. They don't just bring products into country, they also set-up distribution channels and create demand for the product. They are essentially marketing organizations.

The import distributor “buys” products from an offshore company and ships them into their country thus taking title to the goods it is importing.

Having purchased the goods and taken them into inventory (stores them in a warehouse or holding yard), the import distributor then sells them to its own customers within country.

The import distributor manages import logistics

The import distributor is like any other distributor, however with the added function of managing the import logistics. This means having knowledge of shipping (or air freighting), importation tariffs, rules and legislation, and managing the process of having goods cleared through customs and a range of other government agencies who act to protect Australia from illegal imports, environmental hazards, or biosecurity hazards.

Some goods attract import tariffs that need to be paid. There are shipping fees, unloading fees, road and rail freight from the port to the import distributor's warehousing and container unloading. Shipping containers need to be cleaned and returned. All of these activities are either managed by the import distributor or outsourced to specialists such as import agents and brokers.

In addition, the import distributor needs to implement risk mitigation through various financial instruments designed specifically for the importing of goods such as insurance, currency hedging, and proof of loading.

Import distribution: making a profit through buying and selling using importing

The import distributor purchases goods, often in large quantities, and resells them at a higher price (makes a profit)

...accepting the risks and rights that come with the ownership of the goods.

There are typically two main types of import distributors:

-

Full-service import distributors: They provide a range of services including buying, creating assortments, breaking bulk, selling, storing, transporting, and financing

-

Drop-shipping distributors: They sell merchandise for delivery directly from the supplier to the customer without physically handling the product. However, they do take title to the goods before delivery to the customer.

An import distributor is different from an importer, who is responsible for obtaining and transporting goods from other countries on behalf of their customer who does not have the resources or expertise.

The import distributor, on the other hand, undertakes delivering goods to retailers or customers within a country.

Exclusive import distribution - a business that represents a single overseas manufacturer and their brands

Offshore manufacturers seeking to develop new overseas markets (pursuing growth through geographic expansion) will seek out import distributors in various overseas countries.

If there is sufficient opportunity, the import distributor may make the strategic decision to specialize only in that manufacturer's products and build their business around being the exclusive import distributor. Often this arrangement comes about from entrepreneurs visiting trade shows overseas and identifying manufacturers who are not currently exporting product to their country "would you like to expand your distribution to Australia? We'd like to become your import distributor."

The import distribution business based on such an exclusive arrangement would feature the following activities performed by the import distributor:

- Logistics: setting-up warehouse storage facilities to receive imported goods and to then pack them and arrange transport to fulfill orders. Typically imported goods arrive in shipping containers, are unpacked at the import distributor's warehouse, and placed in to inventory (put on shelves and entered in the inventory management software). Orders received from customers are then picked from the shelves and typically dispatched to distributors and customers on pallets.

- Protecting intellectual property: Registering trademarks for the manufacturer's products in Australia.

- Business infrastructure: Importing various goods requires tracking of orders placed, current inventory on hand, and bookkeeping to monitor financial transactions. Other management functions and staffing are required to facilitate customer service, accounting, warehouse staff, and other operational and management functions.

- Supply chain management: one of the biggest challenges of import distribution is managing the supply chain. Most goods are imported using sea freight, hence there is usually a considerable delay waiting for the product to be freighted to port, loaded on the ship, the ship takes weeks sailing, and upon arrival in Australia, needs to be unloaded and product passed through customs. Further delays can occur when the manufacturer requires orders to be placed before they start manufacturing the goods.

It is not unusual for this chain of events to stretch over many months. The import distributor must therefore carefully forecast future demand for product and place orders aiming to optimize the balance between being able to supply its Australian distributors BUT not tying-up too much working capital in stock.

Each of these steps in the supply chain (purchasing, freight, shipping, customs) requires working with suppliers overseas and the management of costs, placing orders, filling out import documentation, insurance, international payments based on proof of loading, problem solving, and re-negotiating contracts. It quickly becomes complex and when things go wrong problem solving needs to be done at a distance, or requires jumping on an aeroplane.

And what do you do if the goods get lost in transit or finally arrive damaged or the order is incorrect? Welcome to import distribution. - Setting-up in-country distribution: Import distributors in Australia work with distributors across the country to warehouse and promote goods to their local markets. Such distribution arrangements need to be set-up.

- Creating market demand: The import distributor's primary function is one of marketing; building brand awareness and product knowledge through promotional activities. Typically this involves trade shows, advertising, and setting-up a sales force to work with distributors and end users to display and demonstrate products, produce quotations, and facilitate sales.

- Product expansion: Import distributors typically start with a handful of the manufacturer's products and after establishing business operations and sales volumes then introducing other products in the manufacturer's range into the market leveraging existing brand awareness and distribution channels.

- Tuning the business model: As sales volumes increase, the import distributor may adjust their business operation to cope with higher volumes and adjust logistics, business infrastructure, staffing, and business systems to improve efficiency and take advantage of new learnings. The import distributor will outgrow the business model they launched the business with. The painful period is inevitably moving from entry-level IT systems to larger enterprise-grade systems that can fully integrate with distributor's systems and freight companies using EDI (Electronic Data Interchange).

Import distribution - improving logistical efficiency when importing into Australia

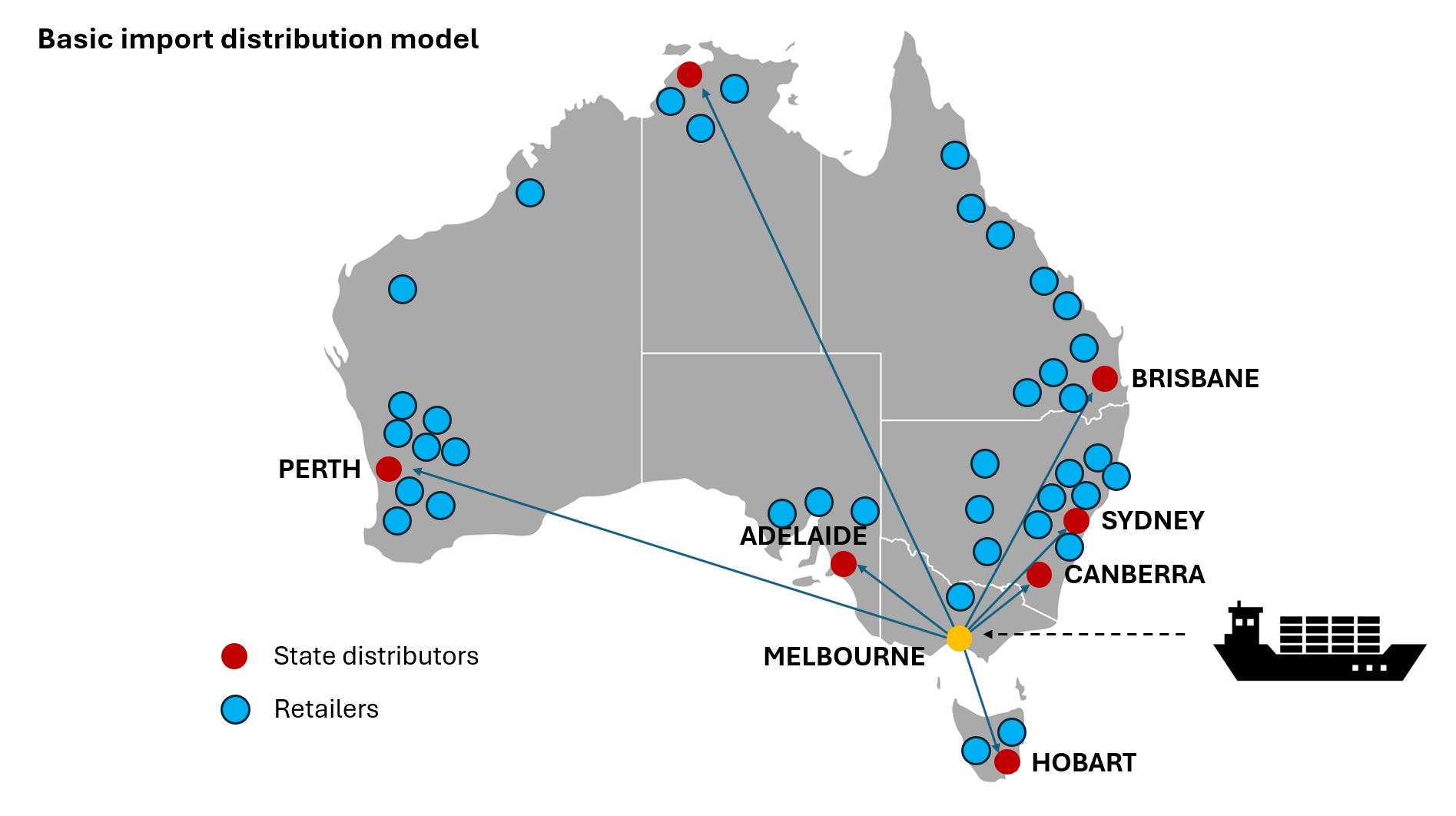

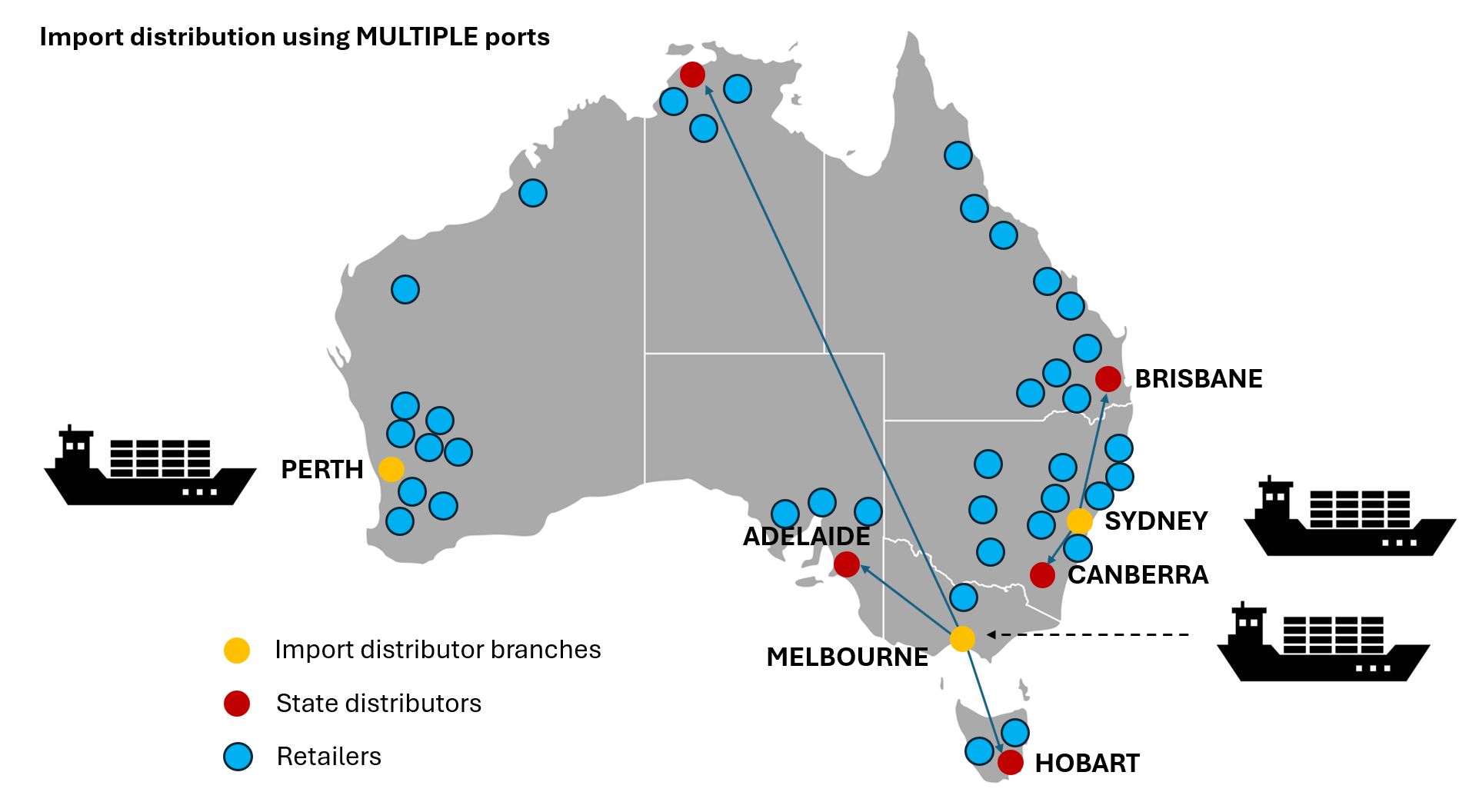

When the import distributor reaches a scale where they are importing multiple container loads of product that then need to be distributed all around the country, it is often more efficient to bring product into the ports closest to the market. Sea freight is less expensive than road freight.

Bringing freight into Sydney., Melbourne, and Brisbane places product closest to 80% of Australia's population which is mostly located on the East coast.

Perth is a special case because freight arriving into Sydney (Australia's busiest port) then has a road trip of about 3,900 km to Perth on the West coast. For this reason, also bringing sea freight into Perth (Fremantle) is the logical choice.

However, this does require setting-up several locations for receiving and warehousing product in 3 locations - Sydney, Melbourne,and Perth. This may obviate the need to use distributors in each of those locations however this places more demands on the import distributor to manage relationships direct with retailers.

In practice, many import distributors use a mixture of distributors and direct selling.

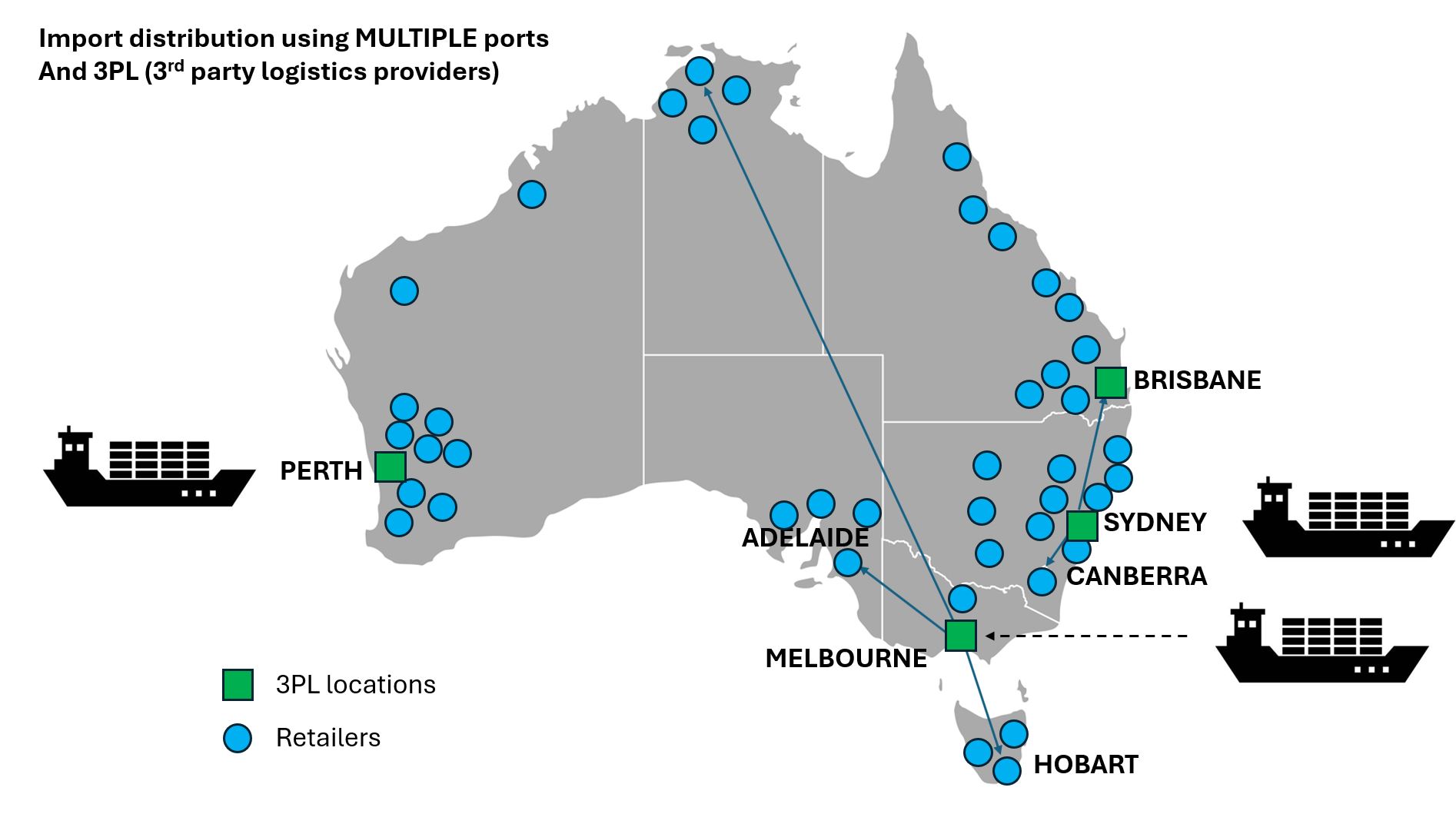

Import distribution - bypassing distributors and going direct to retail using 3PL

Due to Australia's small population size and concentration of the population along the East coast of Australia (Sydney, Melbourne, and Brisbane cities account for 33% of the population, and the Eastern States - Queensland, New South Wales, ACT, and Victoria account for 80% of the population) combined with the efficiency of road freight overcomes the need to appoint wholesalers and distributors when distributing many imported goods.

However, for FMCG and industrial consumables, it is advantageous to warehouse the product close to retailers and small specialist wholesale distributors that service B2B end-users. In this case many import distributors are opting to use Third Part Logistics companies (3PL) to warehouse and distribute their products.

3PL's warehouse product however, their customers (the import distributor for example) retains ownership of the goods.

The 3PL companies can receive containers of product (after clearing customs), unpack them, and take the goods into their warehouse. The 3PL provides warehousing on a fee for service basis and does not "buy" the product from the import distributor as a distributor would. Thus the 3PL simply executes order fulfillment on instruction from the Import Distributor, picking and packing the products and dispatching them to the retailer or business end user.

This model has the following features and implications:

No distributor mark-ups: 3PLs charge fees for storage and handling. These are single digit percentages compared with distributor margins which often add +50% to the product price. National retail chains negotiate hard on buy price - there isn't room for another hefty margin in the supply chain.

Price control: When there is a distributor in the supply chain, the import distributor cannot dictate the sell price. When dealing with national retail chains where a single buy price has been negotiated for all their stores across the country, the import distributor cannot maintain that sell price working through regional distributors.

No sales and marketing: 3PLs offer warehousing and logistical support only. Distributors provide sales and marketing in their regions. Using 3PLs instead of distributors means the import distributor must undertake more sales and marketing activity.

No customer support: Whereas distributors would provide local customer support to handle product enquiries, ordering, and problem solving - 3PLs do not provide this service. The import distributor instead provides centralized customer support.

More consistent control over branding and messaging: Working through distributors adds another link in the message chain where the signal can be distorted and lose impact. Dealing direct with the market allows the import distributor to have greater control and clarity when engaging in promotional activity. Further, regional distributors have many brands and products to promote and may not devote sufficient resources to promoting the import distributor's brands and products. Many function more as wholesalers than true distributors.

Lower insurance cost because inventory is spread over multiple locations: Insurers calculate less risk to import distributors who do not hold all of their inventory in one location. Risk covers not just product replacement (should it go up in smoke) but also lost profits and reputational damage. If an import distributor loses their entire inventory it can be up to 12 months before they are in a position to restore supply to their customers - if they still have any. Only losing (say) one third of stock is an easier position to recover from.

The need for Electronic Data Interchange (EDI): For efficiency, working with multiple 3PLs requires the import distributor's computer to talk to the 3PLs' computers. It is much easier to track inventory in multiple locations, place orders, and arrange freight if data is exchanged over the internet rather than through telephone calls and email. Some 3PL's won't even bother. Hence, the first step to setting-up a 3PL model is to migrate to an ERP system that can track inventory in multiple locations and communicate via EDI.

Outsourcing importing logistics to agents: Importing into several ports around the country requires people skilled in import logistics. Many import distributors outsource this work to import agents who take care of both ends of the importing process - buying freight, paper work and loading at the country of origin, tracking freight across the water and through transit ports, customs clearance, tariffs, fees and charges, insurance, trucking from port to the 3PL, container unloading, container cleaning and return. Such companies can perform these services at any port and have a deep knowledge and experience of this. Arguably, doing this work in-house doesn't make sense - there are many traps for young players.

A model needed to work with large retail chains: In Australia, the retail landscape is dominated by large retail chains. In FMCG - Woolworths, Coles, Aldi, Big W, K-mart and in hardware and hardware and plumbing Bunnings, Mitre 10, Reece, Tradelink - in virtually every product category there exist national chains. Due to the downward cost pressure exerted by chains and their buying power, there isn't room in the distribution chain for multiple middle men. The 3PL model strips the supply chain down to the bone but provides both product inventory in each state near to retail outlets while adding minimally to product cost.

Outsourcing warehouse and order fulfillment: Having 3PL's manage warehousing and inventory reduces staffing costs and the hassle of managing more people. In addition reduces capital tied-up in warehouse buildings and infrastructure (racking, automation, forklifts etc.) or leasing same.

Operational flexibility: 3PL outsourcing enables reducing warehouse and staffing costs in response to business conditions. Inventory can shrink or grow in response to market conditions. When the import distributor owns and operates these facilities costs remain the same even when times are tough and/or they run out of warehouse space when the business expands.

It should be noted that the 3PL model is most suited to:

FMCG products, critical spares, and business consumables: Retailers hold minimal stock and rely on suppliers to frequently replenish. Having stock proximate to retail outlets speeds order fulfillment and reduces trucking costs. Equally, mining companies and manufacturers who rely on suppliers holding spare parts needed to fix processing machines that break down, don't want to wait several days for parts to arrive.

Pass-through products that require minimal value-adding: 3PLs have limited capability to work on products to assemble or modify them. For example some industrial valves require different bolt patterns drilled into their connection flanges depending on the customer's application. While the product itself is largely standard - this made to order modification requires machining. Rarely would a 3PL provide this service. 3PL's are best suited to handling products that remain in their original packaging.

Summary

An import distributor is a business that purchases products from overseas sources and brings them into the country for local sales and distribution. They handle both the logistical aspects of importing and the marketing efforts to build brand awareness and demand for the products.

Key functions include:

- Purchasing and Shipping: Buying products from offshore companies and shipping them into the country.

- Warehousing and Inventory Management: Storing products in warehouses and managing inventory.

- Sales and Distribution: Selling products to local customers and managing distribution channels.

- Import Logistics: Handling shipping, import tariffs, customs clearance, and other regulatory requirements.

- Risk Mitigation: Using financial instruments like insurance and currency hedging to manage risks.

There are several main types of import distributors:

- Full-Service Import Distributors: Provide a range of services including buying, storing, selling, and financing.

- Drop-Shipping Distributors: Sell products directly from the supplier to the customer without handling the product physically.

- Specialized import distributors: Import distributors may also specialize in representing a single overseas manufacturer, becoming exclusive import distributors. This involves additional responsibilities like protecting intellectual property, managing supply chains, and creating market demand.

In Australia, import distributors often use third-party logistics (3PL) companies to handle warehousing and distribution, which can reduce costs and improve logistical efficiency. This model allows import distributors to focus more on sales and marketing while 3PLs manage the logistical aspects.