07 December 2019

Solution selling - how to avoid the vampire project

Cycling is about maximising human performance through optimum engineering but also selecting and configuring the machine that is best fit for purpose.

So, while this article appears to be about cycling, this is merely a "vehicle" to convey the concept that, too often solution sales firms take on “Vampire Projects” through being mesmerised by a new work opportunity and the lure of solving an interesting engineering challenge.

As I ride my bike up the hill, I see my heart rate is at 154 – for an old bloke that’s not bad. It's the highest heart rate I can sustain for the 25 minutes it takes me to climb the hill. Despite puffing hard I was still being humiliated by younger, fitter cyclists overtaking me while chatting amicably to the rider next to them. Such is life.

I am thinking, would this be easier if I had a better bike?

Cyclists only need the smallest justification for buying a better bike.

This is where the impartial input of a 3rd party (my wife) can provide much needed but unwanted sanity.

“Is it about making it easier, or is it about the exercise? – in which case a worse bike would be the practical decision.”

You're missing the point; cycling is as much about the gear as it is about the exercise.

Never stand between a man and the acquisition of a more impressive toy.

What’s this got to do with business?

If you are not a cyclist, you will not appreciate the engineering marvel that a bicycle is.

The diamond frame shape was arrived at over 100 years ago and is close to the most perfect design for converting human power into forward motion.

Bicycles are a well thought through and evolved compromise of competing objectives…

- Biomechanically suited to humans

- Least weight for required strength

- Compromise between conservation of energy and comfort

- Provides attachment points for necessary equipment (cranks and pedals, something to sit on, handlebars, brakes, gears etc.)

- And a marvel in international standardisation enabling thousands of manufacturers to supply a bewildering array of components creating infinite configurations to suit taste, budget, performance, and bragging rights.

That’s what businesses are – a well thought through compromise.

The trick with cycling is choosing the right bike for the task; in business optimum performance comes from configuring your organisation for maximum throughput and quality at minimum capital and operating cost.

Perfection is not possible, pragmatic excellence is.

Excessive baggage will weigh you down. When building a lean, mean, competitive business - less is more.

Of course, there are bikes that can be used for anything – they work, but they’re not competitive.

The lesson here is that to optimise business performance you need to direct resources toward a particular chosen purpose. Focus is important.

Are you road racing, hill climbing, track racing, down hilling, riding dirt tracks or popping down to the shops?

There’s a best bike for each.

Setting up an organisation aiming at a broad range of work types is possible but won’t compete against a thoroughbred organisation tightly calibrated for a specific task.

The reality is many businesses are still pedalling the same bike from years ago, perhaps with a new bell and some coloured streamers sticking out of the ends of the handlebars.

So, how does one strip down the organisation to create a competitive thoroughbred configured for the task without a shred of dead weight?

The process is to tightly define what work you are best at and design your organisation around that definition. Narrowing the definition, while still servicing a market of sufficient volume is the key principle.

What is your business mission?

Decide what business you are in and determine what type of work fits that definition.

Easier said than done. I work with many different business types (although 90% are B2B), the engineering-based organisations (from software development through to metal fabrication) find defining exactly what business they are in hard.

The problem stems from…

- They are run by clever people able to adapt to new challenges

- New challenges are an enjoyable creative outlet for their talents

- They don’t like turning down work

- They're not good at marketing their special capability, so they bid on anything that moves

The last point deserves further comment; if you are not getting sufficient enquiry for your special capability, then you might conclude market demand is low.

Forgetting, of course, that buyers are not clairvoyant - you need to tell them - that's what marketing does.

Vampire projects

So, any new opportunity that loosely fits their capability (“we could make that”) is afforded much thinking time and is squeezed in.

Problems occur and either the project is a technical disaster, is delivered late, and/or is sold at a punishing loss. We've all done it.

In the meantime, bread-and-butter work is pushed aside and way too much management and engineering focus is drained by the blood-sucker project.

Engineering types love to tinker and love the challenge of a new project. They also only need the slightest excuse to buy a new piece of kit (see bicycles above).

This is where you need to decide – is it a hobby or a business?

I am as guilty of this as anyone, often taking on difficult assignments because they are interesting rather than good business.

And of course, conventional wisdom says those who succeed in business - do something they love.

Thing is, for all of us involved in selling solutions, some types of work are easier, and yet still deliver good value to the client. That’s the sweet spot in business.

We should all be identifying the types of jobs that just sail through the organisation and chase (market) more of them.

Define your value chain

Businesses are machines that add value. Clients buy value.

For example, distribution businesses add value by researching the market for suitable products, making them conveniently available and providing information and advice on selection and application.

Engineering firms take loosely specified problem definitions, tighten up the requirements specification, design a solution and then build it.

Each of these businesses has a distinct set of logical steps to build value - a value chain.

Explanations of what a value chain are are plentiful on the internet but to my mind, they are a bit academic.

I like to think of businesses as a sausage machine; you put raw material in (business inputs), crank the handle driving the raw material through a series of processes and out the end pops something you can invoice.

Leaning up the business requires working through each step of the value chain and…

- Defining the work methods (this is how we make a sausage)

- Writing policy and procedures (this is the recipe and rules for making sausages)

- Plant and equipment (this is the gear needed to make sausages)

- People (finding the best people for each task, training and supervising them)

- Standards (this is the specification for the type of sausage we make)

The critical decision is not what you will bid for, but what types of work you won't.

Making that decision enables you to choose the right processes and equipment to best achieve maximum value at the lowest cost.

To try to win projects outside your normal scope can mean bidding at a lower margin against the guys who are geared up for that type of work.

If you win the job you have two problems; you not good at it and you have less room to absorb cost overruns.

Many of the organisations I work with sell bespoke solutions. Typically, taking a brief, designing a system or a product to fit that brief, and if the customer likes the proposal, they receive an order to build and deliver.

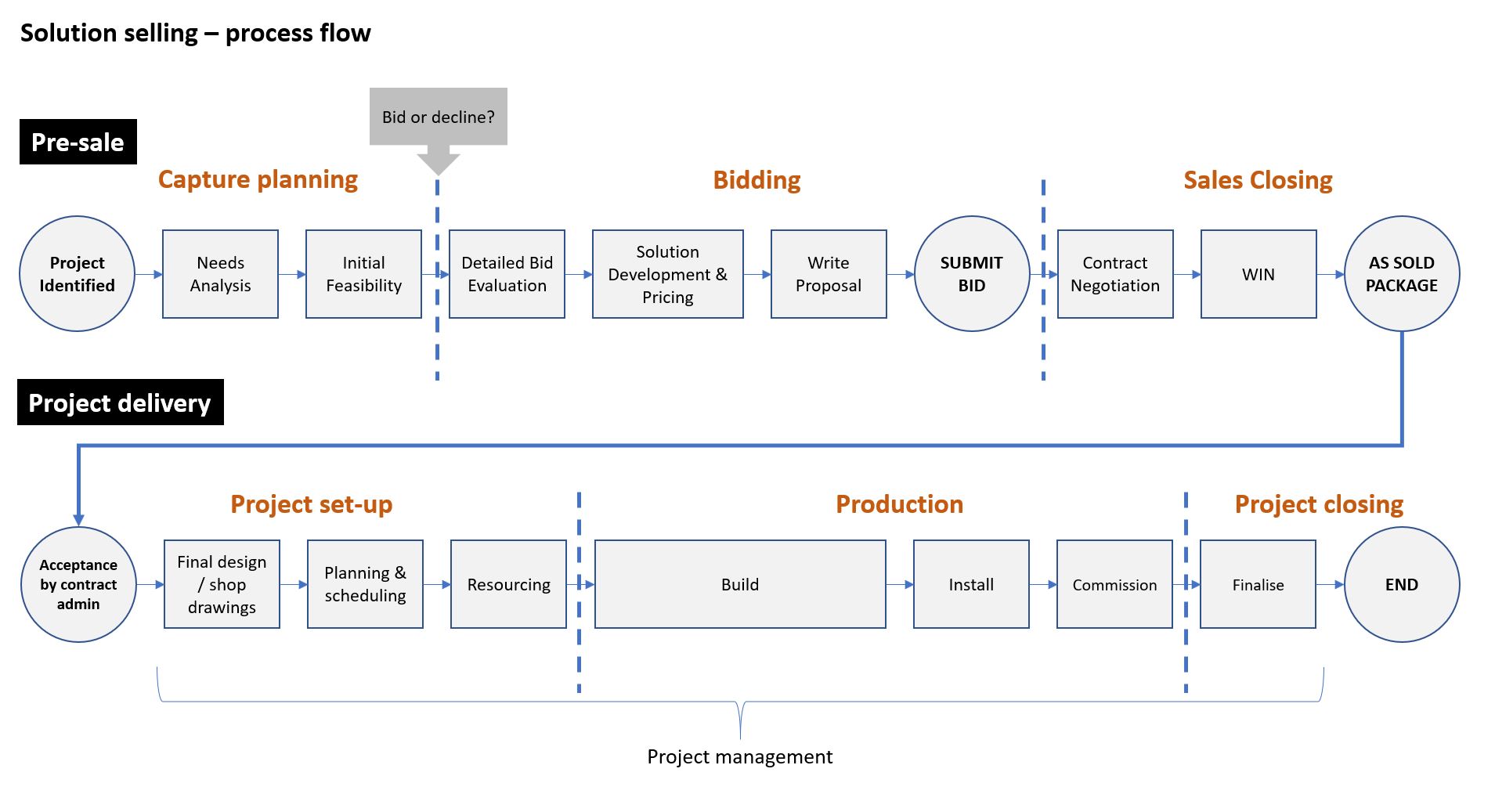

This is what the sausage machine looks like…

Most organisations have an implicit understanding of the above steps but have never mapped it out. The evidence for this comes out when running workshops to define the value chain…

- The proposition that the organisation could be so simply defined is at first rejected - “every job is different” – actually, they all follow the same steps.

- Rigid process would be constraining. “Some jobs come in and are out the door the same day, to have to go through each of these steps would slow us down” – not if it is done efficiently, and actually –jobs that jump the queue notoriously cause chaos. Chaos = cost.

- Re-orders: ‘Clients sometimes call-up and order the same product again – how does that fit the model?” – you simply jump through each step very quickly.

However, it is one thing to understand this process, it's another to implement it with discipline. Many problems in design and construction businesses arise from not completing each step before moving to the next. For example, starting project delivery before the AS-SOLD package is complete.

Standardised processes enable optimisation.

Many years ago, I was the marketing manager for a casino. Like any organisation, casinos have developed special ways of doing things. On the gaming, floor croupiers are taught to deal cards and operate all games using precisely defined movements.

In all businesses, there is a most efficient way to do anything.

Hand movements for example are so strictly choreographed that trained casino staff notice out of the corner of their eye when a movement is incorrect. The choreography achieves several things…

- Easier detection of cheating

- Faster training

- Faster hand-rates

McDonald's does the same thing when teaching teenagers to make hamburgers. Systematisation drives efficiency and consistency.

The value chain map provides the basis for studying every step and working out the most efficient method and then writing procedures. The work never stops, the concept of continuous improvement is monitoring when the current method fails, working out why and then implementing a better procedure.

Of course, the less focused the business is, the more complex writing standard procedures becomes (if it happens at all). Consistency, low cost and high quality becomes more elusive.

Defined processes ensure quality and consistency is inevitable

The first step in devising a quality system is defining the organisation’s value chain. Every business has a process for receiving a request for an order and fulfilling that request (however elaborate) to achieve a sale. This process can be mapped.

Deciding what business you are in, mapping the process and optimising performance based on this process is the method for building an efficient and profitable business.

Like the bicycle, the aim is to achieve the most perfect design for converting human effort into future profits.

However, perfect design is dependent on the task to be performed.

So that’s the bike and your business discussed.

That leaves the other thing that can be adjusted to improve performance – The Rider.

Further reading